Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

0755-22277778

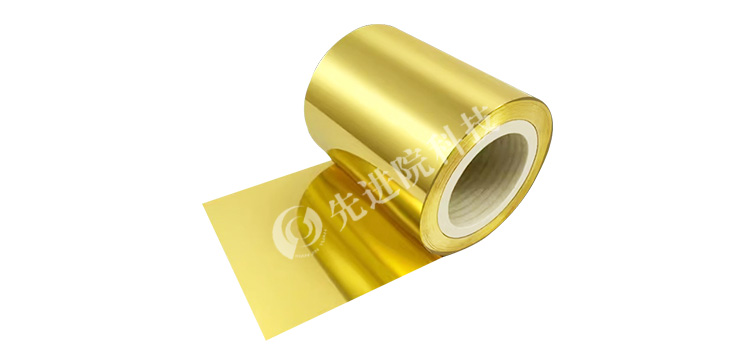

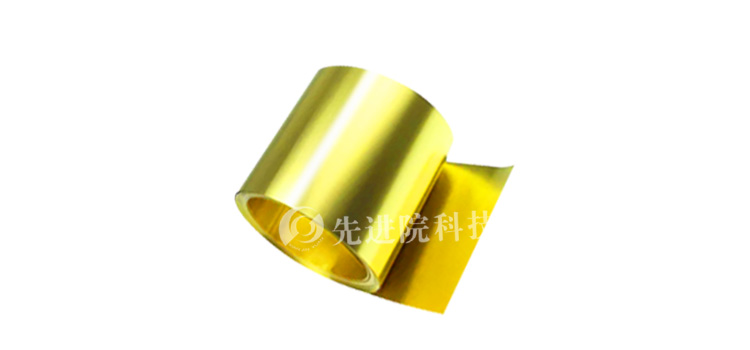

PET镀金膜是一种应用广泛的表面处理材料,用于增加材料的耐磨损性、化学稳定性和光学性能。PET镀金膜通常是通过在聚对苯二甲酸乙二醇酯(PET)表面镀上一层金属薄膜制成的。

产品特性

金属光泽:PET镀金膜表面呈现出独特的金属光泽,这种光泽不仅提升了产品的视觉质感,还使其在众多产品中脱颖而出。

耐磨耐损:由于镀金层的存在,PET镀金膜具有较高的硬度和耐磨性,能够抵抗日常使用中的划痕和磨损。

电磁屏蔽:镀金层还赋予了PET镀金膜优异的电磁屏蔽效果,能够有效阻挡外部电磁干扰,保护内部电子元件。

化学稳定性:PET基材本身具有良好的化学稳定性,能够耐受多种化学物质的侵蚀,镀金后更是增强了其耐腐蚀性能。

加工性能:PET镀金膜具有良好的柔韧性和加工性能,可适应不同的弯曲和变形需求,同时也可轻松应用于各种形状和尺寸的表面。

生产工艺

涂覆底漆:在PET薄膜表面涂覆一层底漆,以提高表面平整度和增强附着力。

化学还原:将含有金离子的溶液均匀地喷涂在PET薄膜上,然后通过化学反应在PET表面形成金属颗粒镀层。这一过程可能涉及真空蒸发、磁控溅射或化学还原法等多种技术。

再次涂覆:在金属颗粒镀层表面再次涂覆一层透明的保护漆,以保护金属镀层不受外界氧化或损伤。

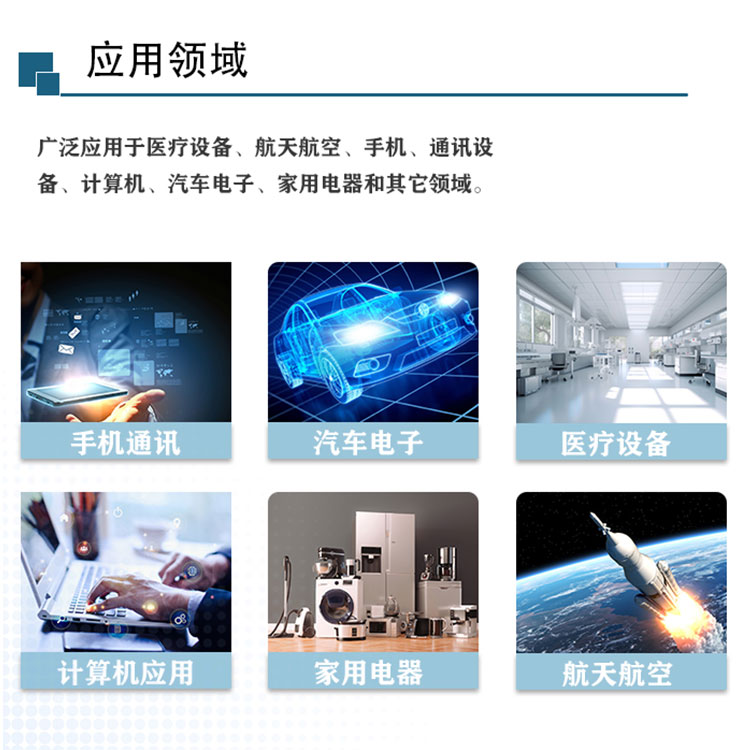

PET镀金膜作为一种高级装饰材料,以其独特的金属光泽、耐磨耐损、电磁屏蔽等优异性能,在电子产品、建筑材料、家具和包装材料等多个领域展现出了广泛的应用前景。

车间展示

先进院(深圳)科技有限公司, © 2021 www.leird.cn. All rights reserved 粤ICP备2021051947号-1 © 2021 www.xianjinyuan.cn. All rights reserved 粤ICP备2021051947号-2