Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

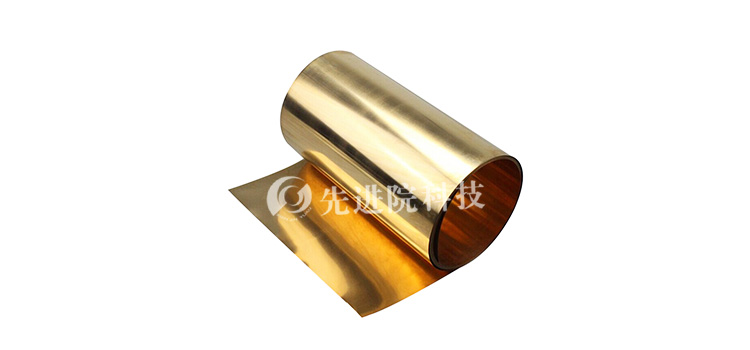

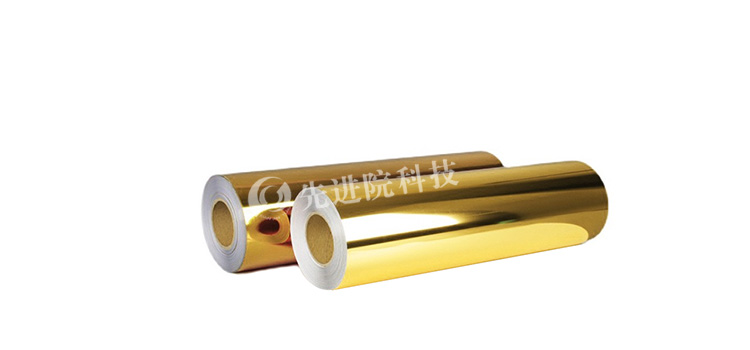

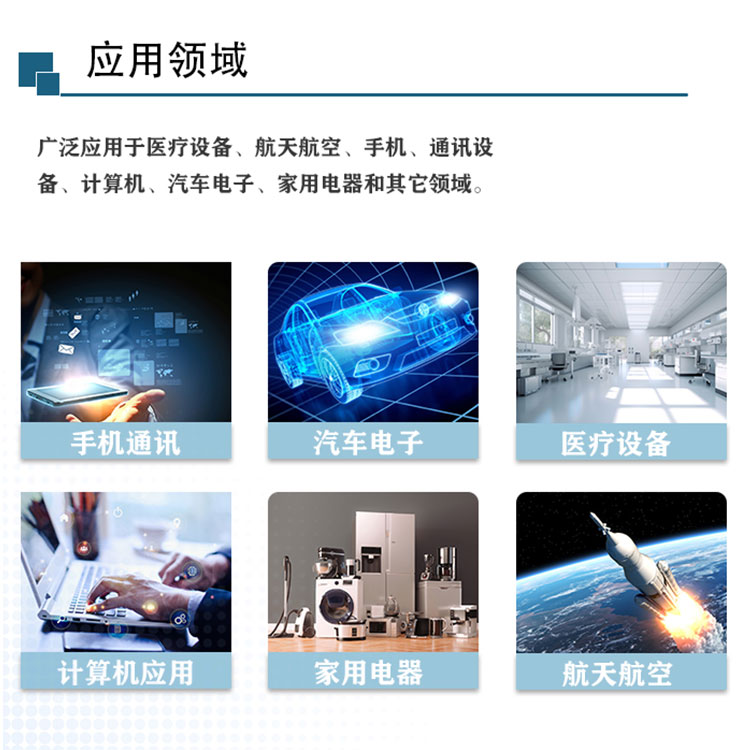

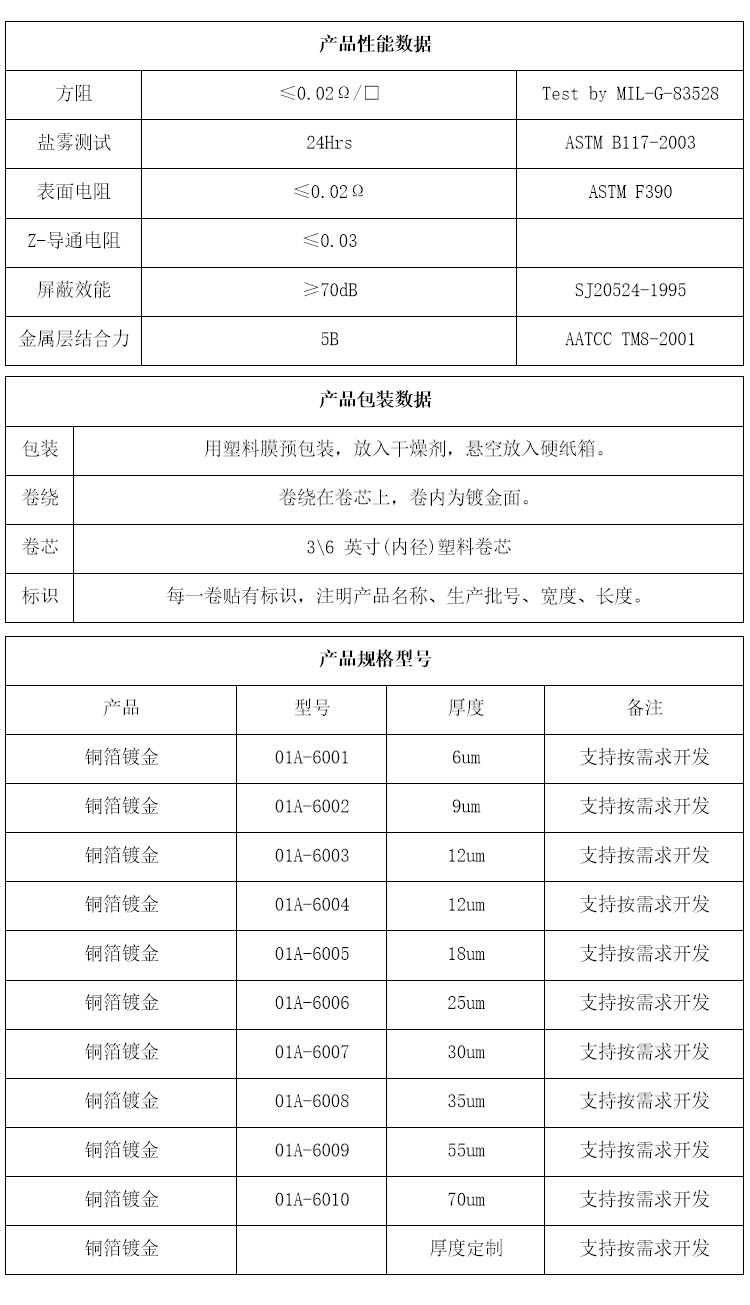

Copper foil gold plating is a process of uniformly coating a thin layer of metal gold on the surface of copper foil. This process not only preserves the excellent conductivity, ductility, and plasticity of copper foil, but also endows it with higher conductivity, corrosion resistance, and decorative effects. Advanced Institute of TechnologyCopper foil gold plating, can be customized in size and thickness according to needs; Welcome to consult.

0755-22277778

铜箔镀金的产品,即镀金铜箔,是一种在铜箔基材表面覆盖有一层金属镀层的薄型金属箔,通常镀层材料为金、银、镍等金属或石墨烯等先进材料。铜箔镀金产品以其独特的性能和广泛的应用领域,在现代工业中扮演着重要的角色。

产品特性

薄型:镀金铜箔的厚度非常薄,如常见的0.018mm厚度,使得其在需要高精度、轻量化的场合具有显著优势。

耐腐蚀:铜箔基材与金属镀层的双重保护层能够有效抵御氧化、腐蚀等化学反应,延长产品的使用寿命。

可塑性:镀金铜箔具有较好的可塑性,可依据需要进行弯曲、切割等加工,方便应用于多种形状的产品中。

电导性:铜箔本身具有良好的电导性能,而金属镀层可以进一步提高其导电性,适用于电子元件的制造等领域。

美观性:金属镀层赋予镀金铜箔良好的外观质感,使其不仅具有功能性,还具备一定的装饰性。

生产工艺

清洗基材:将铜箔基材通过机械或化学方法进行清洗,去除表面的杂质和氧化物,以确保金属镀层的附着力。

镀金处理:将清洗后的铜箔基材置于电镀槽中,通过电解的方式将金属镀层均匀地覆盖在基材上。金属镀层的选择可以根据具体需求进行,如金、银、镍等。

表面处理:对镀金后的铜箔进行打磨、抛光等工艺处理,以提高其表面光洁度和美观度。

检测和包装:对镀金铜箔进行质量检测,如厚度、电导性等指标,合格后进行包装,以便运输和使用。

车间展示

先进院(深圳)科技有限公司, © 2021 www.leird.cn. All rights reserved 粤ICP备2021051947号-1 © 2021 www.xianjinyuan.cn. All rights reserved 粤ICP备2021051947号-2