Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

+86-13826586185

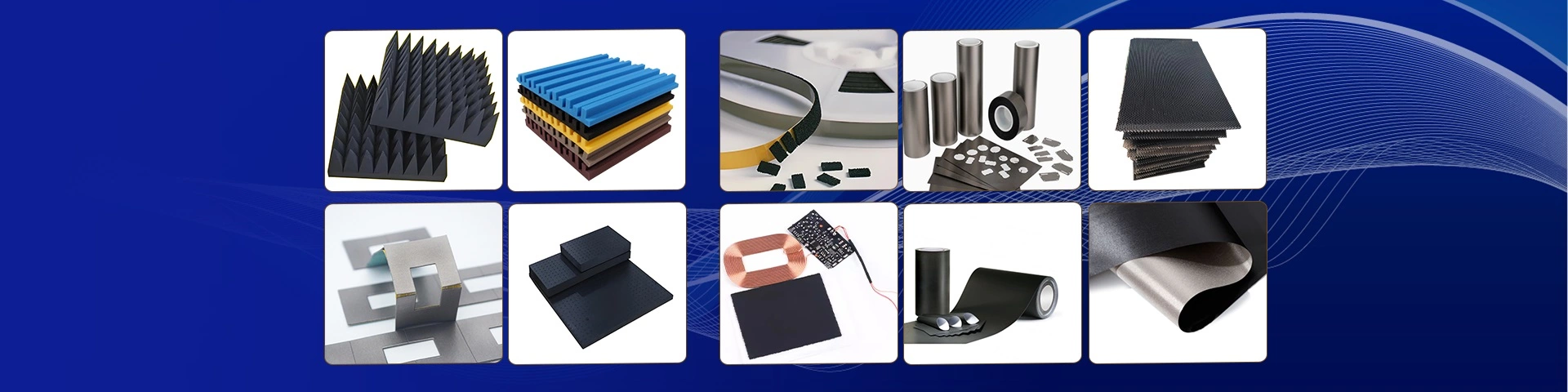

Carbon black -absorbing material is a material that can absorb electromagnetic wave energy and has a wide range of application scenarios.

1. Cybers black suction mechanism: Carbon black is a material composed of carbon particles. Its surface has a rich microporous structure and a high ratio area, which can effectively convert electromagnetic wave energy into thermal energy and absorb it. In addition, charcoal black also has conductivity and can improve the suction performance of the material.

2. Application of charcoal black -absorbing materials: Carbon black -sucking materials are widely used in aerospace, electronic communications, radar stealth and other fields. In aerospace, carbon black suction materials can reduce the radar reflex signal of the aircraft and improve stealth performance; in electronic communication, charcoal black suction materials can reduce electromagnetic radiation interference and improve the quality of communication.

3. Design principles of carbon black suction material: The design of the carbon black suction material should be considered as the factors such as its absorption frequency, the stability of the suction performance, and the feasibility preparation of process preparation. Properly control the amount, particle size and distribution of charcoal black, which can regulate the suction performance.

4. Preparation method of charcoal black suction material: Common carbon black-absorbing material preparation methods include solitary-gel method, electric spinning method, carbonization method, etc. Among them, the solution-gel method can prepare carbon black materials with higher ratio surface area and pore rate. The electric spinning method can prepare nano-class carbon black fibers. Carbonization method can prepare silicon with high electrical and suction performance. Material.

5. The development trend of charcoal black suction wave materials: At present, the research of charcoal black suction materials is mainly concentrated in the improvement of performance and the expansion of application. In the future, the development trend includes further improving the suction performance of materials, reducing preparation costs, and expanding application fields.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2